HIGH SPEED Aluminium Foil Container Machine with long life

Specification:

1. Raw material: Aluminum foil; Thickness: 0.035mm~0.12mm;

Alloy: 8011, 8006, 3003, 3005 etc.;

2. Japan Inverter, PLC and 10inch touch screen control system;

3. Max. Width of Aluminum foil: 1000mm;

4. Max. Diameter of Aluminum foil: 700mm;

5. Core diameter of Aluminum foil: 76/152mm;

6. Working speed: 40-65 times/min;

7. Total Power: 9-11kw;

8. Compressed air needed: 0.5- 0.8 Mpa, 0.2m3/min;

9. Install dimension: 10000*4500*4500mm;

CHOCTAEK's machine advantages :

(1) This production line can work automatically. Worker control and regulate this production line through electric control equipment.

(2) The width of decoiler is about 1300mm.

(3) The feeding system control feeding length and stepping by computer, which assure a high-precision steps.

(4) We can design and manufacture different machines on request.

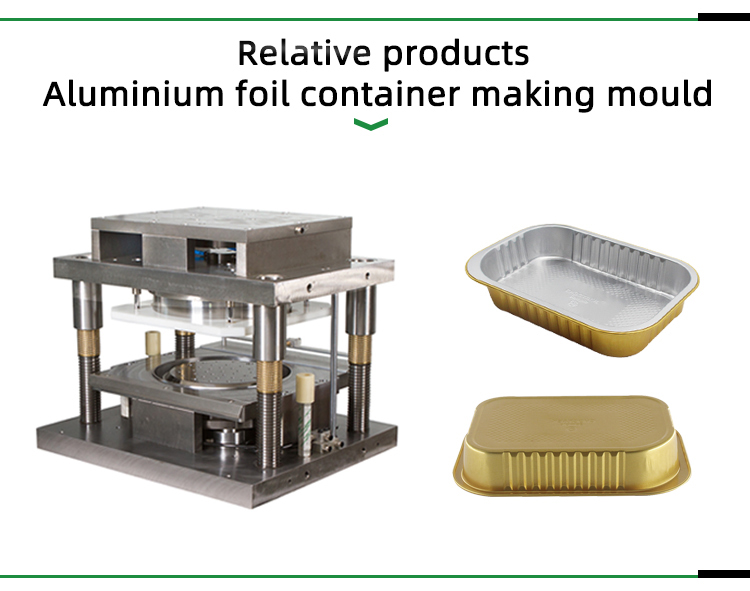

(5) The press may be equipped with single cavity or multi-cavity moulds for wrinkle-wall or smooth-wall container production.

We imports different high quality processing machines to ensure the precision of aluminium foil container making machine and mould.

Besides the machine, we manufacture the aluminium foil container making machine in our CHOCTAEK workershop.

We can make 1/2/3/4/6/8 cavities mould according to customer's requirements.

The aluminium foil container making machine and mould will be packed in wooden case which is suitable for sea navigation.

For more CHOCTAEK aluminium foil container making machine and mould details, please feel free to contact with Essia:

E-mail: essia@choctaek.com

Phone/Whatsapp: 0086-18927205885

Why Choose CHOCTAEK

We developed and produced 2300 sets of aluminum foil container moulds from 2003 to August 2021

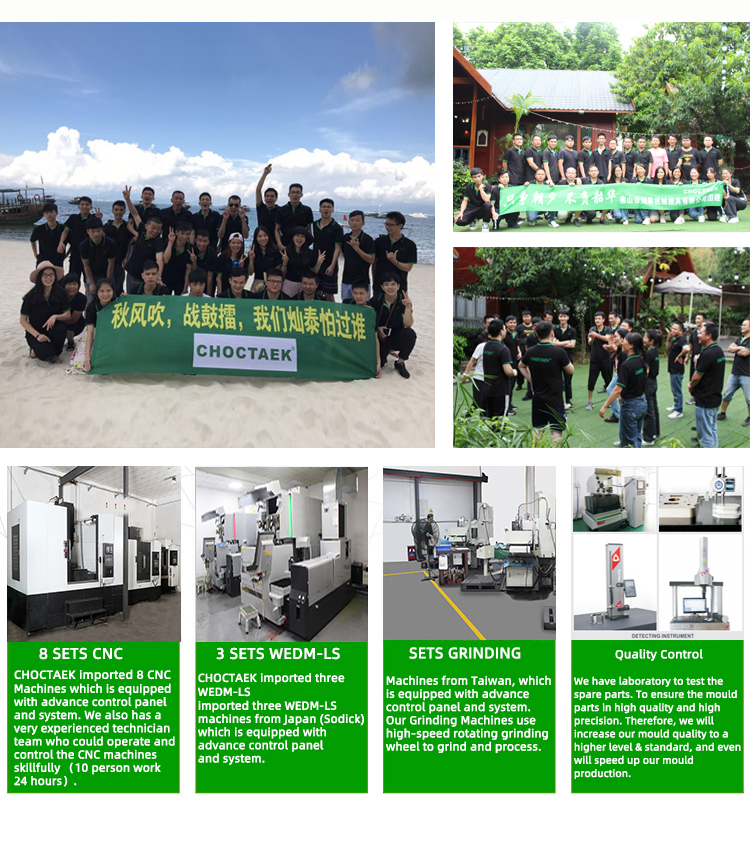

Technical Team

- We have a senior technical team (technicians have worked in our company for more than 10 years).

Processing the mould in CHOCTAEK

We have 8 sets of CNC machines, low speed wire cutting machines and other equipment, so we can control the accuracy of the mold very well.

Quality Control

We have our testing room to test the spare part.