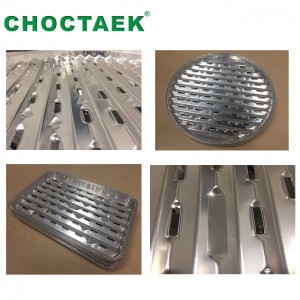

High Speed 45T Semi-automatic Aluminum Foil Container Production Line

High Speed 45T Semi-automatic Aluminum Foil Container Production Line

Components:

1. Auto-lubricated foil feeder

2. Control panel

3. Length of controller

4. 45 ton punch machine

5. Semi-automatic stacker

6. Foil scrap aspirator (Optional)

7. Foil scrap collecting system (Optional)

The features of machine:

1. This is semi automatic machine. This machine is suitable for working small moulds with high speed. Its stroke is 40-70 times/min.

2. The operating control panel is euipped with a large 10inch touch screen (SIEMENS) allowing quick set up of machine parameters and visualization of production flow. With this design, workers can control and operate the machine and mould easily and convenient.

3. The key electrical appliance adopt imported elements in famoud brand, such as SCHNEIDER, SAMCO from Japan ect.

4. So, CHOCTAEK's machine work stable & smooth, high precission & long life.

Packing & shipment

Packing: The auto-lubricated feeder, length controller, control panel, stacker and aluminium foil container moulds are packed in wooden case. Punch, sucker and pipe are packed in plastic films, after that punch is fitted on wooden stock/base in order to carry or carriage and transportation.

About specifications, kindly pls contact us.

Email: vanessa@choctaek.com

Mob & WhatsApp: 86 18028178413

COMPANY OVERVIEW

Providing the whole solution for producing aluminum foil container

We Have More Than 20+ Years Practical Experience In This Industry

We "Choctaek Machinery Mould Limited" are professional manuafacturer of aluminum foil container machine, aluminum foil container mould and relative equipments. Till to 2021, we have developed and produced over 2500 sets aluminum foil container moulds. Each mould is different from others. In these two years, we are developing the smooth-wall container machine and mould to match the market need. We are keeping on upgrading our technology to ensure quality, and we can customize moulds to meet the special needs of customers all over the world.