High Quality Aluminium Foil Container Press Die

1. Product introduction

| Material | Stainless Steel |

| Treatment | High-temperature heat |

| Application | Machinery & hardware |

| Usage | Making Aluminum foil container |

| name | Aluminium foil container mould |

| Cavity | Single and Multi- Cavities |

| Type | Smooth/wrinkle-wall container mould |

| Style | One compartment or multi-compartment |

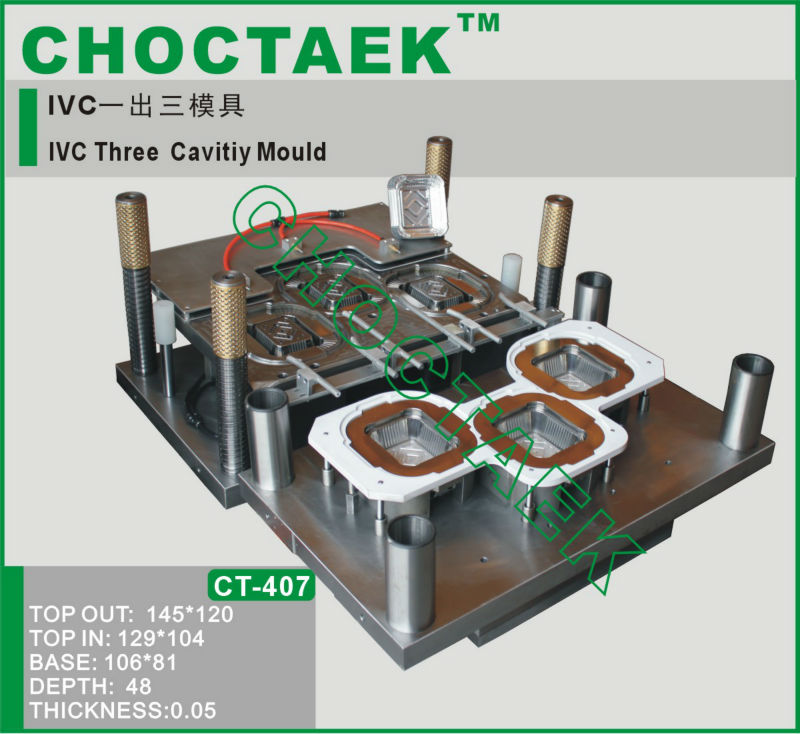

| Rim | Full/ IVC/ Folded / Reverse rim |

| Guarantee | One year |

| After-sales Service Provided: Engineers available to service machinery overseas | |

3. Feature of Product

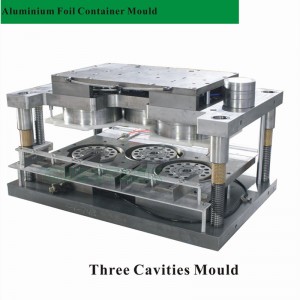

3.1 Specification: single cavity mould, 2, 3, 4, 5 cavities, ect.

3.2 Brand: CHOCTAEK.

3.3 Place of Origin: Foshan, China.

3.4 Driven Type: Pneumatic.

3.5 Packaging Type: packed in seaworthy wooden case.

3.6 Application: To produce aluminium foil containers for food package.

CHOCTAEK imported three WEDM- LS machines from Japan (Sodick), which is equipped with advance control panel and system.

Please feel free to call us when you are interested in Aluminium Foil Container Making Machine and Mould project.

E-mail: essia@choctaek.com

WhatsApp/Wechat:0086 18927205885

4. Packaging & Shipment

Packaging type: Packed in wooden case.

Port of shipment: Guangzhou, Shenzhen, Chinese Port.

We manufacture high technology mould for many customers. We can produce several different rim configurations to meet the customer’s requirements including G rim, L rim, IVC and so on.

We build up all of our mould with the high quality material. Flow areas are heat treated for proper hardness. These quality controls ensure reliable moulds for long life.

CHOCTAEK imported 8 CNC machines which is equipped with advance control panel and system. We also has a very experienced technician team who could operate and control the CNC machines skillfully (10 person work 24 hours).