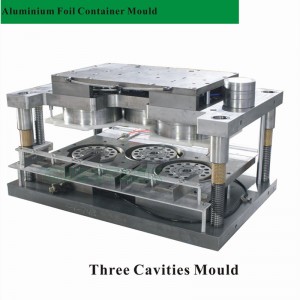

Full Curling Aluminium Foil Container Mould

1. Features

1.Moulds are built with high quality steel. Flow area is heat treated for better hardness, which ensure our mould in long operating life.

2.Moulds adopts pneumatic rebound device which makes the mould more flexible.

3.Our excellent processing technical ensure that the mould can complete the cutting, shaping, blanking and curing by one step.

4.Our excellent processing technical ensure that the mould can complete moulds such as single cavity or multi-cavity mould, moulds for the production of various containers with different rims (G style, L style, IVC or Folded style).

Both design and manufacturing is fully integrated with a highly advanced state of the art 3d cad/cam package. This facilitates a seamless transition from design to machining. The net result is a precision tool produced in a timely manner.

Tools can be configured to function in almost any type of press.

We pride ourselves on a tool design that is simple and robust. Easy to set- up and run, your company and staff will not be faced with excessive down time maintenance and related costs.

We can produce tools for both Wrinkle Wall and Smooth Wall type, in all styles and shapes currently on the market. We also develop any challenging concept you may require.

Tools come with integrated air cushions requiring only external air supply. All air supply ports are cross drilled integral to the tool to eliminate external plastic lines and fittings. Thru hardened high quality tool steels and fasteners are used.

Only advanced and tested technology is incorporated into your tool build.

2. Product introduction:

1. The moulds that we design and produce are suitable for almost every kinds of machine or press.

2. We produce mould with the best quality steel in China. And some main mould areas are made high-temperature head treatment for proper hardness, which ensure moulds are in great quality

and long life.

3. To meet customers’ different requirement, we design and manufacture the mould in several rims,such as G rim, L rim, H rim, and IVC etc.

4. We can design and produce the mould in multi-cavities, no matter it is one compartment container or multi-compartment container.

5. In order to save foil material cost, we has innovated “zero-web” moulds. this kind of moulds will reduce lots of foil scrap.

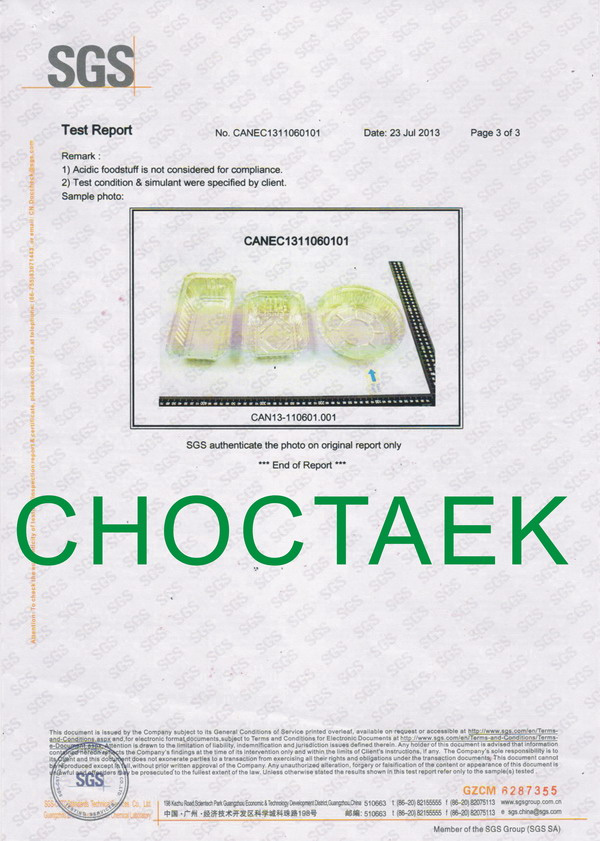

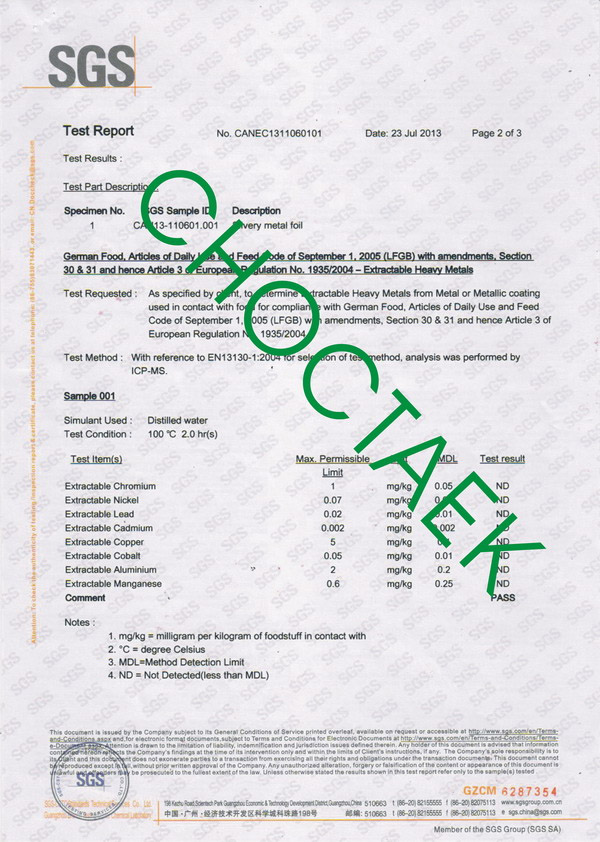

3. Certifications

4. Advanced Manufacturing Equipments

We has a very experienced technician team who could operate and control the these machines skillfully. With these two machines, we could process the mould parts in high quality and high precision.

5. Details of Mould Parts

6. Sample Room

Till June on 2021, we have developed and produced more than 2000 sets aluminum foil container moulds which are in different sizes and shapes.

7. FAQ

1. Q: How To Manufacturing Aluminium Foil Containers

A: The manufacturing of aluminium foil containers can either take place in a medium or large quantiy. A typical machine can make aluminium foil containers ranging from 40 microns to 140 microns. The machine consists of several parts that come into the manufacturing process.

2. Q: What is the raw material?

A: 3003-H24, 8011-H22, 8006-HO

3. Q: What is the thickness?

A: 0.03- 0.3mm.

4. Q: What is the delivery date?

A: Wrinkle wall aluminium foil container making mould is about 60- 75days. Smooth wall aluminium foil container making mould is about 85-100days.

Please feel free to call us when you are interested in Aluminium Foil Container Making Machine and Mould project.

E-mail: essia@choctaek.com

WhatsApp:0086 18927205885