CHOCTAEK brand aluminium foil container production line

| C700 | C1000 | C1300 | |

| Max. Width of Roll: | 700mm | 730mm | 1000mm |

| Length of Strokes: | 220 | 220 | 250 |

| Feeding Length: | 20-999 | 20-999 | 20-999 |

| Feeding Accuracy : | ±0.3 | ±0.3 | ±0.3 |

| Working Voltage: | 3-380 | 3-380 | 3-380 |

| Total Power | 9KW | 9KW | 11KW |

| Weight of machine: | 6.6T | 7.0T | 8.0T |

Hot Sale Food Aluminum Foil Container Production Line CHOCTAEK C1300 Configuration: Decoiler Press 80Tons With Electronic Feeder Electronic Control Panel And Pneumatic Control Units Stacker 3 Or 4 Lines Scrap Foil Collection System The Main Body Of C1300 Machine Is A "H"-Frame 80T...

The advantages as below:

-Top safety, when open the door, the machine will stopped.

-The replacement of the mold is convenient and easy to operate.

-It’s suitable for large size single cavity, medium and small multi-cavity moulds.

-Main motor is made by Siemes.

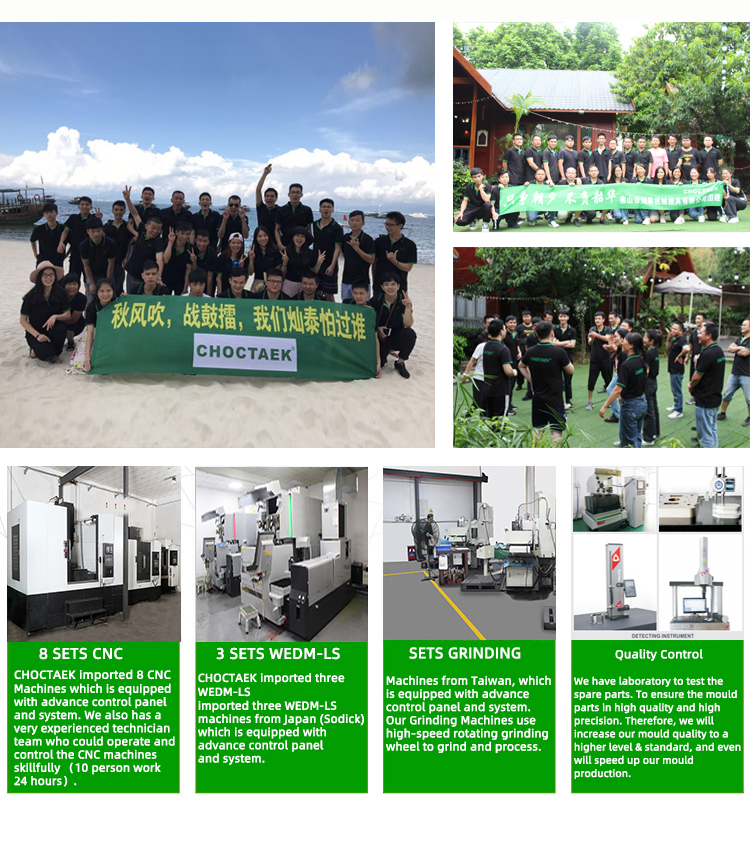

We imports different high quality processing machines to ensure the precision of aluminium foil container making machine and mould.

Besides the machine, we manufacture the aluminium foil container making machine in our CHOCTAEK workershop.

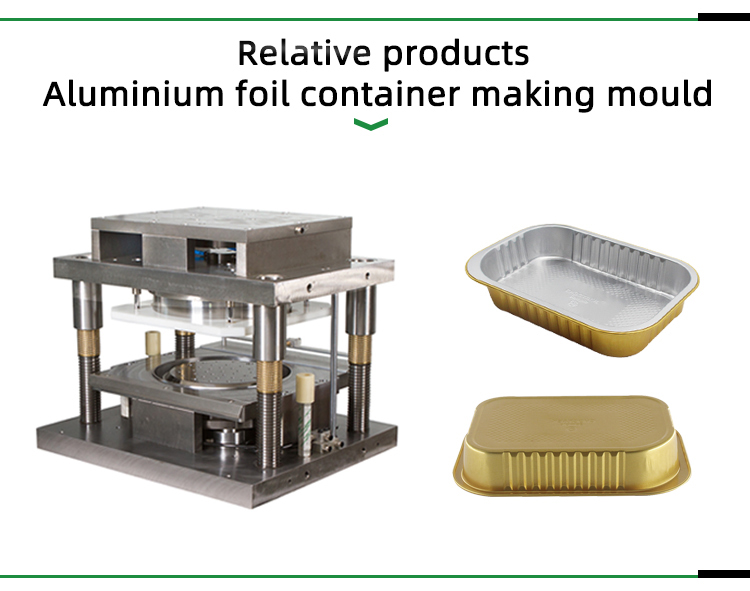

We can make 1/2/3/4/6/8 cavities mould according to customer's requirements.

We CHOCTAEK developed and produced 2300 sets aluminum foil container moulds which are in different sizes and shapes from 2003 to 2021.

For more CHOCTAEK aluminium foil container making machine and mould details, please feel free to contact with Essia:

E-mail: essia@choctaek.com

Phone/Whatsapp: 0086-18927205885

Why Choose CHOCTAEK

We developed and produced 2300 sets of aluminum foil container moulds from 2003 to August 2021

Technical Team

- We have a senior technical team (technicians have worked in our company for more than 10 years).

Processing the mould in CHOCTAEK

We have 8 sets of CNC machines, low speed wire cutting machines and other equipment, so we can control the accuracy of the mold very well.

Quality Control

We have our testing room to test the spare part.